公司信息及水印

| 牌号简介 About |

|---|

| Vydyne® 75HB NT0679是一种PA66基共聚物,具有高熔融强度和理想的剪切减薄行为、高拉伸强度、延展性和提高透明度,使其成为吹塑和铸膜应用的理想选择。熔融温度介于PA6和PA66之间,与PA6和PA66的物理混合物相比,它是首选材料,因为它能够在较低的温度下加工并产生均匀的薄膜,从而产生均匀的熔融行为、高光泽和清晰度。此外,与PA66均聚物相比,75HB的结晶速度较慢,因此可提高工艺灵活性。 Vydyne 75HB NT0679 is a PA66-based copolymer that features high melt strength with ideal shear thinning behavior, high tensile strength, ductility, and improved clarity, making it ideal for blown- and cast-film applications. Having a melt temperature between PA6 and PA66, it is a preferred material of choice compared to physical blends of PA6 and PA66 due to the ability to process at lower temperatures and produce a homogenous film, resulting in uniform melting behavior, high gloss and clarity. Further, 75HB also allows for improved process flexibility due to its slower crystallization rate versus PA66 homopolymers. |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

密度 Density |

1.14 | g/cm³ | ISO 1183 |

|

粘数(H2SO4(硫酸)) Viscosity (H2SO4 (sulfuric acid)) |

254 to 269 | cm³/g | ISO 307 |

|

体积密度 bulk density |

674 | g/l | ASTM D1895 |

|

含水量 water content |

0.10 | % | ASTM D6869 |

|

相对粘度 Relative viscosity 2 |

165 to 195 | ASTM D789 | |

|

机械性能 MECHANICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

拉伸强度 tensile strength |

ASTM D882 | ||

|

屈服 yield |

MPa | ISO 527-2 | |

|

TD,断裂,吹塑薄膜 TD, fracture, blow molded film |

MPa | ASTM D882 | |

|

MD,断裂,吹塑薄膜 MD, fracture, blow molded film |

MPa | ASTM D882 | |

|

Ultimate Ultimate 3 |

MPa | ASTM D882 | |

|

Ultimate Ultimate 4 |

MPa | ASTM D882 | |

|

弯曲强度 bending strength |

MPa | ISO 178 | |

|

薄膜 film |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

割线模量 Secant modulus |

|||

|

1% 正割,TD,铸造薄膜 1% secant, TD, cast thin film |

MPa | ASTM D882 | |

|

1% 正割,MD,铸造薄膜 1% secant, MD, cast thin film |

MPa | ASTM D882 | |

|

拉伸强度 tensile strength |

ASTM D882 | ||

|

屈服,吹塑薄膜 Yield, blow molded film 3 |

MPa | ASTM D882 | |

|

屈服,吹塑薄膜 Yield, blow molded film 4 |

MPa | ASTM D882 | |

|

拉伸应变 Tensile strain |

ASTM D882 | ||

|

断裂 fracture |

% | ISO 527-2 | |

|

TD,断裂,铸造薄膜 TD, fracture, cast thin film |

% | ASTM D882 | |

|

MD,断裂,挤塑薄膜 MD, fracture, extruded film |

% | ASTM D882 | |

|

屈服,铸造薄膜 Yield, cast thin film 3 |

% | ASTM D882 | |

|

屈服,铸造薄膜 Yield, cast thin film 4 |

% | ASTM D882 | |

|

落锤冲击 Drop hammer impact 5 |

|||

|

铸造薄膜 Casting thin film 5 |

g | ASTM D1709 | |

|

撕裂强度 tear strength |

|||

|

TD,铸造薄膜 TD, cast thin film |

g | ASTM D1922 | |

|

MD,铸造薄膜 MD, cast thin film |

g | ASTM D1922 | |

|

冲击性能 IMPACT |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

悬臂梁缺口冲击强度 Impact strength of cantilever beam notch |

|||

|

23℃ 23℃ |

kJ/m² | ISO 180 | |

|

热性能 THERMAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

熔融温度 Melting temperature |

℃ | ISO 11357-3 | |

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

| 2 Formic acid |

| 3 (TD) |

| 4 (MD) |

| 5 (f50) |

|

【新闻资讯】查看全部

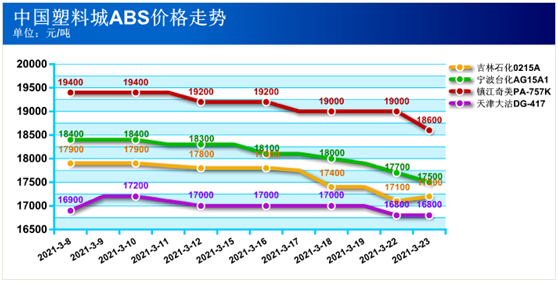

苯乙烯深陷下行通道 ABS/PS如临大敌?

2021-03-24 搜料网资讯: 由于中美谈判影响,3月19日苯乙烯价格被国际原油利空捆绑迎来大幅下挫走势,虽然3月22日苯乙烯有超跌反弹表现,但近期持续性的下行走势仍将深远影响ABS和PS市场后市 |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付