公司信息及水印

| 牌号简介 About |

|---|

| R525J NT0721是一种天然的25%玻璃填充高流量PA66,通过电中性热稳定剂进行热稳定。它专门为需要高介电强度、低导电性和耐腐蚀性的电气应用而设计。 R525J NT0721 is a natural, 25% glass-filled, high-flow PA66 that is heat-stabilized with an electrically neutral heat stabilizer. It is specially designed for electrical applications requiring high dielectric strength, low conductivity and corrosion resistance. |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

密度 Density |

1.32 | g/cm³ | ISO 1183 |

|

模具收缩率 Mold Shrinkage Mold Shrinkage |

ISO 294-4 | ||

|

TD:23℃,2.0 mm,干燥 dry TD: 23 ℃, 2.0 mm, dry |

0.90 | % | ISO 294-4 |

|

MD:23℃,2.0 mm,干燥 dry MD: 23 ℃, 2.0 mm, dry |

0.40 | % | ISO 294-4 |

|

吸水率 Water Absorption Water Absorption |

|||

|

平衡 equilibrium,23℃,50% RH,干燥 dry Equilibrium balanced, 23 ℃, 50% RH, dry |

2.0 | % | ISO 62 |

|

23℃,24hr,干燥 dry 23 ℃, 24 hours, dry dry |

0.90 | % | ISO 62 |

|

机械性能 MECHANICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

拉伸模量 Tensile Modulus Tensile Modulus |

|||

|

23℃,干燥 dry 23 ℃, dry |

MPa | ISO 527-2 | |

|

23℃,湿润 cond. 23 ℃, moist cond |

MPa | ISO 527-2 | |

|

拉伸应力 Tensile Stress Tensile Stress |

|||

|

断裂 break,23℃,干燥 dry Break, 23 ℃, dry dry |

MPa | ISO 527-2 | |

|

断裂 break,23℃,湿润 cond. Break, 23 ℃, wet cond |

MPa | ISO 527-2 | |

|

拉伸应变 Tensile Strain Tensile Strain |

|||

|

断裂 break,23℃,干燥 dry Break, 23 ℃, dry dry |

% | ISO 527-2 | |

|

断裂 break,23℃,湿润 cond. Break, 23 ℃, wet cond |

% | ISO 527-2 | |

|

弯曲模量 Flexural Modulus Flexural Modulus |

|||

|

23℃,干燥 dry 23 ℃, dry |

MPa | ISO 178 | |

|

23℃,湿润 cond. 23 ℃, moist cond |

MPa | ISO 178 | |

|

弯曲强度 Flexural Strength Flexural Strength |

|||

|

23℃,干燥 dry 23 ℃, dry |

MPa | ISO 178 | |

|

23℃,湿润 cond. 23 ℃, moist cond |

MPa | ISO 178 | |

|

泊松比 Poisson's ratio |

ISO 527-2 | ||

|

冲击性能 IMPACT |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

简支梁缺口冲击强度 Charpy notched Impact Strength Charpy Notched Impact Strength |

|||

|

23℃,干燥 dry 23 ℃, dry |

kJ/m² | ISO 179/1eA | |

|

23℃,湿润 cond. 23 ℃, moist cond |

kJ/m² | ISO 179/1eA | |

|

-30℃,干燥 dry -30 ℃, dry |

kJ/m² | ISO 179/1eA | |

|

-30℃,湿润 cond. -30 ℃, moist cond |

kJ/m² | ISO 179/1eA | |

|

简支梁无缺口冲击强度 Charpy unnotched Impact Strength Charpy Unnotch Impact strength |

|||

|

23℃,干燥 dry 23 ℃, dry |

kJ/m² | ISO 179/1eU | |

|

23℃,湿润 cond. 23 ℃, moist cond |

kJ/m² | ISO 179/1eU | |

|

-30℃,干燥 dry -30 ℃, dry |

kJ/m² | ISO 179/1eU | |

|

-30℃,湿润 cond. -30 ℃, moist cond |

kJ/m² | ISO 179/1eU | |

|

悬臂梁缺口冲击强度 Impact strength of cantilever beam notch |

ISO 180 | ||

|

23℃,干燥 dry 23 ℃, dry |

kJ/m² | ISO 180 | |

|

23℃,湿润 cond. 23 ℃, moist cond |

kJ/m² | ISO 180 | |

|

-30℃,干燥 dry -30 ℃, dry |

KJ/m² | ISO 180 | |

|

-30℃,湿润 cond. -30 ℃, moist cond |

KJ/m² | ISO 180 | |

|

热性能 THERMAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

热变形温度 HDT Hot deformation temperature HDT |

|||

|

1.8 MPa,未退火 unannealed,干燥 dry 1.8 MPa, unannealed, dry |

℃ | ISO 75-2/A | |

|

0.45 MPa,未退火 unannealed,干燥 dry 0.45 MPa, unannealed, dry |

℃ | ISO 75-2/B | |

|

熔融温度 melting temperature Melting temperature |

℃ | ISO 11357-3 | |

|

线性热膨胀系数 CLTE Linear coefficient of thermal expansion CLTE |

|||

|

TD:23~55℃,2 mm,干燥 dry TD: 23~55 ℃, 2 mm, dry |

E-6/K | ISO 11359-2 | |

|

MD:23~55℃,2 mm,干燥 dry MD: 23~55 ℃, 2 mm, dry |

E-6/K | ISO 11359-2 | |

|

相对温度指数 RTI Relative Temperature Index (RTI) |

|||

|

电气性能 Elec Electrical performance Elec |

UL 746 | ||

|

0.75 mm,干燥 dry 0.75 mm, dry |

℃ | UL 746 | |

|

1.5 mm,干燥 dry 1.5mm, dry |

℃ | UL 746 | |

|

3.0 mm,干燥 dry 3.0 mm, dry |

℃ | UL 746 | |

|

强度机械性能 Str Strength mechanical performance Str |

UL 746 | ||

|

0.75 mm,干燥 dry 0.75 mm, dry |

℃ | UL 746 | |

|

1.5 mm,干燥 dry 1.5mm, dry |

℃ | UL 746 | |

|

3.0 mm,干燥 dry 3.0 mm, dry |

℃ | UL 746 | |

|

冲击机械性能 lmp Impact mechanical performance lmp |

UL 746 | ||

|

0.75 mm,干燥 dry 0.75 mm, dry |

℃ | UL 746 | |

|

1.5 mm,干燥 dry 1.5mm, dry |

℃ | UL 746 | |

|

3.0 mm,干燥 dry 3.0 mm, dry |

℃ | UL 746 | |

|

电气性能 ELECTRICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

体积电阻率 Volume Resistivity |

|||

|

1 mm,干燥 dry 1 mm, dry |

ohms·cm | IEC 60093 | |

|

介电强度 Dielectric Strength Dielectric Strength |

|||

|

1 mm,干燥 dry 1 mm, dry |

kV/mm | IEC 60243 | |

|

耐电弧性 Arc Resistance Arc Resistance |

|||

|

3.0 mm,干燥 dry 3.0 mm, dry |

ASTM D495 | ||

|

相比漏电起痕指数 Comparative Tracking Index Compared Tracking Index |

|||

|

3.00 mm,干燥 dry 3.00 mm, dry |

V | IEC 60112 | |

|

高电弧燃烧指数(HAI) High Arc Burning Index (HAI) |

UL 746 | ||

|

0.75 mm,干燥 dry 0.75 mm, dry |

UL 746 | ||

|

1.5 mm,干燥 dry 1.5mm, dry |

UL 746 | ||

|

3.0 mm,干燥 dry 3.0 mm, dry |

UL 746 | ||

|

高电压电弧起痕速率 HVTR High voltage arc marking rate HVTR |

|||

|

HVTR,干燥 dry HVTR, dry |

UL 746 | ||

|

热丝引燃 HWI Hot wire ignition HWI |

|||

|

0.75 mm,干燥 dry 0.75 mm, dry |

UL 746 | ||

|

1.5 mm,干燥 dry 1.5mm, dry |

UL 746 | ||

|

0.4 mm,干燥 dry 0.4 mm, dry |

UL 746 | ||

|

阻燃性能 FLAME CHARACTERISTICS |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

阻燃等级 Flame Class Rating Flame Class Rating |

UL 94 | ||

|

0.75 mm,干燥 dry 0.75 mm, dry |

UL 94 | ||

|

1.50 mm,干燥 dry 1.50 mm, dry |

UL 94 | ||

|

3.00 mm,干燥 dry 3.00 mm, dry |

UL 94 | ||

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

|

【新闻资讯】查看全部

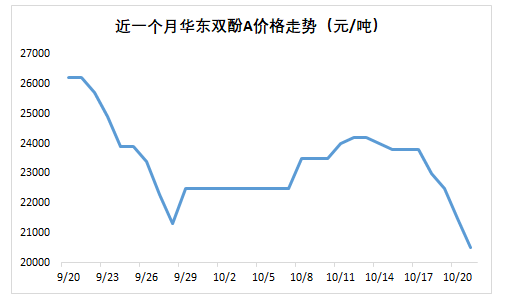

“煤超疯”全军覆没,环氧树脂继续大幅下行

2021-10-22 搜料网资讯: 本周前几日,市场有两大值得关注的热点:一是煤价大幅下跌,二是双酚A竞拍冷清,环氧树脂市场大步下行。 国常会定调,依法打击煤炭市场炒作 国务院总理李克强20日 |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付