公司信息及水印

| 牌号简介 About |

|---|

| 塑料和聚合物化合物长期存在不受控制地积聚和释放电荷的问题。因此,由它们制成的产品会产生静电和轻微的震动,当某些产品放入其中时,这些震动会引发爆炸。解决这一问题的两种传统方法是:(a)使用抗静电添加剂,这种添加剂只在特定条件下(例如潮湿时)起作用,其效果只是暂时的;(b)加入炭黑,这种炭黑自然会使化合物变黑,并且在美学上不具吸引力。PTFA 25是寻求解决这些问题的创新发展。它是一种无烯无卤阻燃化合物,具有永久抗静电性能,不呈黑色,可着色。用于敏感容器的注塑成型。 Plastics and polymeric compounds suffer the perennial problem of accumulating and releasing electrical charges in an uncontrolled manner. Hence products made from them generate static electricity and minor shocks, which can initiate explosions when certain products are placed in them. The two traditional ways of solving this problem are (a) to use antistatic additives, which only work under certain conditions (e.g. when damp) and the effect of which is only temporary; and (b) to incorporate carbon black, which naturally turns the compound black and aesthetically unattractive. PTFA 25 is an innovative development in the quest to solve these problems. It is an olefinic-based halogen-free flame-retarded compound with permanent antistatic properties, it is not black and it can be coloured. It is intended for the injection-moulding of sensitive containers. |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

熔体质量流动速率 Melt Flow Rate |

|||

|

230℃,2.16kg 230℃,2.16kg |

58 | g/10min | ISO 1133 |

|

冲击性能 IMPACT |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

悬臂梁无缺口冲击强度 Notched impact strength of cantilever beam |

ISO 180 | ||

|

-20℃ -20℃ |

10 | kJ/m² | ISO 180 |

|

20℃ 20℃ |

23 | kJ/m² | ISO 180 |

|

电气性能 Electrical performance |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

表面电阻率 Surface resistivity 2 |

1.0E+10 | ohms | IEC 60093 |

|

阻燃性能 FLAME CHARACTERISTICS |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

3.00 mm 3.00 mm |

V-0 | UL 94 | |

|

补充信息 Supplementary information |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

UV Stability UV Stability |

kLy | ||

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

| 2 after 6 months |

|

【新闻资讯】查看全部

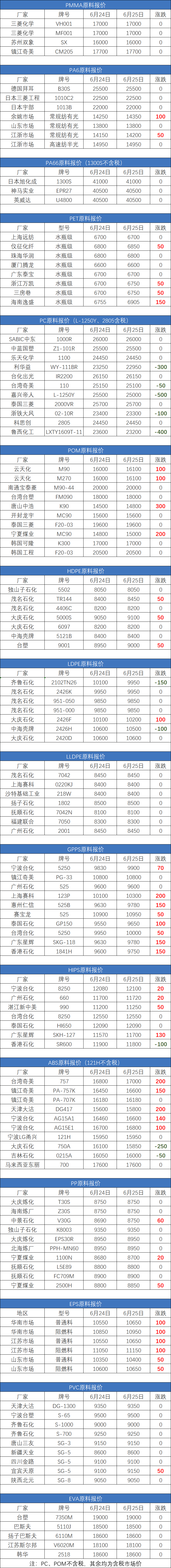

6月25日 国内ABS/PS/PP/PVC/PA塑料行情报价

2021-06-25 搜料网资讯: PE:本周国内聚乙烯市场价格延续涨势,上游原油价格震荡向上,对聚乙烯市场交易心态有所提振,本周线性期货多高开强势运行,同时消息面听闻中东某国家高压货源近 |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付