公司信息及水印

| 牌号简介 About |

|---|

| 技术:选择性激光烧结风形GT是一种基于聚酰胺纤维玻璃的深黑色复合材料。手工完成后,颜色变得明亮。Windform GT是聚酰胺材料系列中一种全新的产品,用于添加剂制造,不仅美观,而且性能方面,因为它具有更高的灵活性,与其他Windform粉末不同。风形GT结合了弹性、延展性和阻力的最佳特性,因此在受到振动和冲击影响的各种赛车和功能应用中,它被认为是一种非常有价值的材料。事实上,材料具有有意义的冲击强度和断裂伸长值,与拉伸强度和弯曲强度的相关值相结合,使其非常适合以“损伤”阻力为前提的应用,以保护组件,例如在发生冲击和/或不当使用时。与其他材料区别的另一个因素是它的特点是防水材料,防潮,因此对液体的吸收。Windform GT也是一种非常轻的材料,每单位密度具有优良的机械性能。应用:汽车应用,在汽车和引擎盖下需要一定的灵活性(如卡扣配合)。它还适用于赛车、空气管道、进气和冷却系统、与液体或油接触的液压管道、传感器的保护罩以及需要良好柔韧性和抗损坏能力的所有应用(例如:靠近地面的赛车部件)。表面光洁度:SLS加工后6.20 Ra祄m手工加工后1.45 Ra祄m数控加工后1.15 Ra祄m Technology: Selective Laser Sintering Windform® GT is a composite material based on polyamide fiber glass, deep and dark black colour. After hand finishing, the colour becomes shining and brighter. The Windform® GT is an absolute new product in the family of polyamide materials for the additive manufacturing not only aesthetically, but also in terms of performance, because it differs from the other Windform® powders thanks to its higher flexibility. Windform® GT combines optimal characteristics of elasticity and ductility and resistance, thus it can be considered a highly valuable material in various racing and functional applications affected to vibration and shocks. In fact, the material has meaningful values of impact strength and elongation at break, which combined with relevant values of tensile strength and flexural strength make it ideal for applications where resistance to "damage" is a prerequisite, in order to preserve the component, for example in case of impact and/or improper use. A further element of distinction from other materials Windform® is its characteristic of being a waterproof material, resistant to moisture and therefore to the absorption of liquids.Windform® GT is also a very light material with excellent mechanical properties per unit density. Applications: Automotive applications where a certain flexibility in the car and under hood (such as snap fit) is required. It is also suitable in motorsport, air ducts, intake and cooling systems, the hydraulic ducts in contact with liquids or oils, in protective cover for sensors and for all applications that need a good flexibility and resistance to damage (for example: racing components near the ground). Surface Finish: After SLS Process 6.20 Ra µm After manual finishing 1.45 Ra µm After CNC machining 1.15 Ra µm |

| 技术参数 Technical Data | |||

|---|---|---|---|

|

物理性能 PHYSICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

密度 Density |

|||

|

20℃ 20℃ |

1.19 | g/cm³ | |

|

机械性能 MECHANICAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

拉伸模量 Tensile modulus |

3290 | MPa | ISO 527-2 |

|

per density unit per density unit |

2760 | MPa | |

|

拉伸强度 tensile strength |

56.2 | MPa | ISO 527-2 |

|

拉伸应变 Tensile strain |

|||

|

断裂 fracture |

15 | % | ISO 527-2 |

|

弯曲模量 Bending modulus |

MPa | ISO 14125 | |

|

per density unit per density unit |

MPa | ||

|

弯曲强度 bending strength |

MPa | ISO 14125 | |

|

per density unit per density unit |

MPa | ||

|

Ultimate Tensile Strength(per density unit) Ultimate Tensile Strength(per density unit) |

MPa/g/cm³ | ||

|

冲击性能 IMPACT |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

简支梁缺口冲击强度 Charpy Notched Impact Strength |

|||

|

23℃ 23℃ |

kJ/m² | ISO 179 | |

|

简支梁无缺口冲击强度 Charpy Unnotch Impact strength |

|||

|

23℃ 23℃ |

kJ/m² | ISO 179 | |

|

热性能 THERMAL |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

热变形温度 Hot deformation temperature |

|||

|

1.8 MPa,未退火 1.8 MPa, unannealed |

℃ | ASTM D648-B | |

|

维卡软化温度 Vicat Softening Temp |

℃ | ASTM D1525 2 | |

|

熔融温度 Melting temperature |

℃ | ISO 11357 | |

|

电气性能 Electrical performance |

额定值 Nominal Value |

单位 Units |

测试方法 Test Method |

|

表面电阻率 Surface resistivity |

ohms | ASTM D257 | |

|

体积电阻率 Volume resistivity |

ohms·cm | ASTM D257 | |

| 备注 |

|---|

| 1 一般属性:这些不能被视为规格。 |

| 2 压 力1 (10N) |

|

【新闻资讯】查看全部

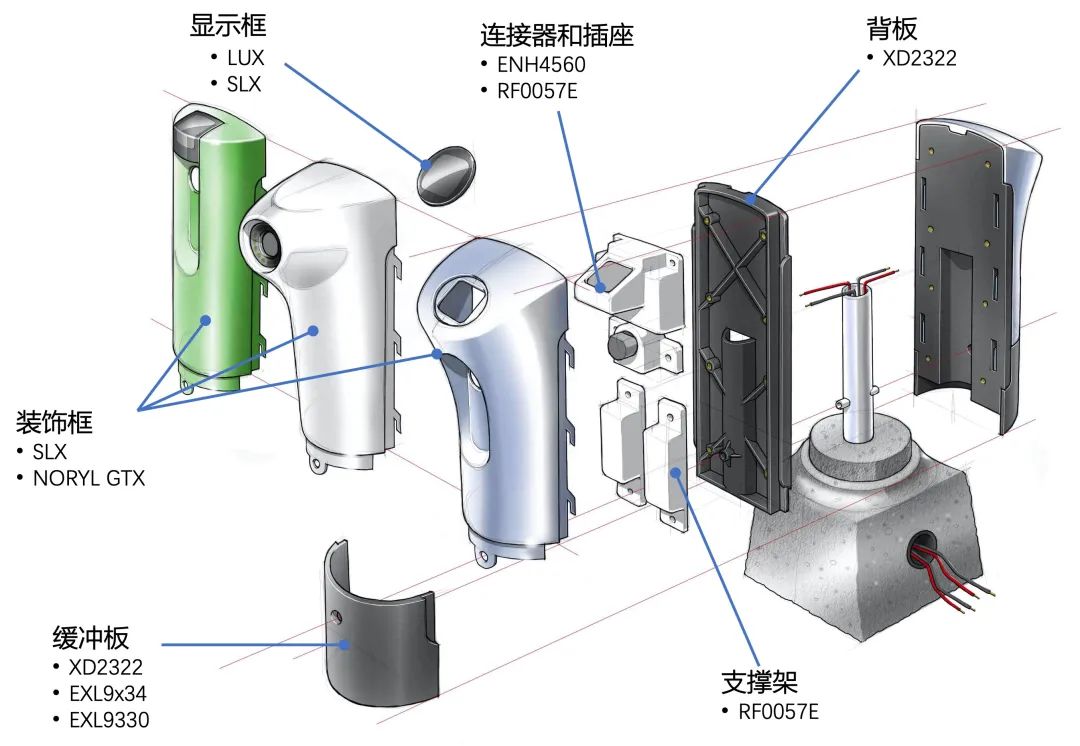

SABIC推出特材新能源汽车充电系统解决方案

2022-04-19 伴随十四五新基建规划的不断落地,首先要加快发展新能源为主体的新型电力系统,有序推进充电桩、配套电网等基础设施的建设。充电桩作为新基建七大领域之一,肩负着重要的时代 |

|

【免责声明】 广州搜料信息技术有限公司保留所有权利。 此数据表中的信息由搜料网soliao.com从该材料的生产商处获得。搜料网soliao.com尽最大努力确保此数据的准确性。 但是搜料公司对这些数据值及建议等给用户带来的不确定因素和后果不承担任何责任,并强烈建议在最终选择材料前,就数据值与材料供应商进行验证。 |

支付宝

支付宝 微信支付

微信支付